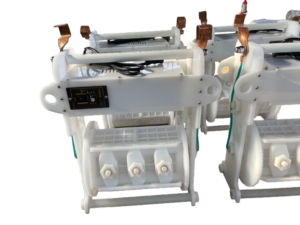

Mini Barrel Plating Machine

- I. Basic Knowledge of Barrel Plating (Part 1)

- 1. What is barrel plating?

- Barrel plating is an electroplating method in which a certain quantity of small parts is placed inside a dedicated barrel. Through indirect electrical conduction while the parts are tumbling, various metal or alloy coatings are deposited onto their surfaces. This process serves the purposes of surface protection, decoration, or functionality.

- 2. Characteristics of barrel plating:

- (1) Barrel plating concentrates scattered small parts within a barrel for processing.

(2) Plating occurs while the small parts are in constant motion and tumbling.

(3) The electrical current is transmitted indirectly during the plating process. - 3. Classification of barrel plating:

- (1) Horizontal barrel plating

(2) Inclined (or oblique) barrel plating II. Applications of the GD Series Variable-Speed Barrel Plating Machine

The WJ Series Variable-Speed Barrel Plating Machine is a versatile solution designed for a wide range of applications:

Specialized Component Plating: It is ideally suited for plating Neodymium Iron Boron (NdFeB) parts with zinc, nickel, copper, and other metals.

Broad Industrial Manufacturing: This machine serves various industries, including electronics, instrumentation, timepieces, writing instruments, and general hardware, for their barrel plating production needs.

Research & Education: It is an excellent tool for laboratory testing, new process development, and serves as practical equipment for student instruction in universities and technical colleges.