Usage Introduction

I. Basic Knowledge of NdFeB Electroplating (Part 1)

The unique properties of NdFeB (neodymium iron boron) material significantly impact the electroplating process.

(1) Influence of High Chemical Activity:

NdFeB is highly chemically active. This characteristic:

① Restricts the use of strong acids or alkalis during pre-treatment.

② Complicates pre-plating (or direct plating). Using simple salt plating baths can easily cause part oxidation, adversely affecting the adhesion between the coating and the substrate.

③ Limits the use of large-sized barrels, as extended processing cycles can lead to severe part oxidation.

(2) Influence as a Magnetic Functional Material:

As a magnetic functional material, the relationship between the coating’s type, combination, thickness, and the product’s magnetic performance must be carefully coordinated.

(3) Influence of Surface Physical Characteristics (Part 1):

The NdFeB surface is porous, loose, and rough. This not only increases the burden of pre-treatment but also makes it difficult to select pre-plating (or direct plating) processes that use complexing agent baths (e.g., alkaline copper, citrate nickel) which offer good adhesion and corrosion resistance but have low current efficiency.

(4) Influence of Surface Physical Characteristics (Part 2):

NdFeB material is brittle and prone to damage from impact. This increases operational difficulties for workers and restricts the use of large-sized barrels, thereby hindering improvements in labor productivity

II. Basic Knowledge of NdFeB Electroplating (Part 2)

1. Pre-treatment Process

Deburring → Water rinse → Electrolytic degreasing → Water rinse → Ultrasonic degreasing → Water rinse → Acid pickling → Water rinse → Ultrasonic water rinse → Activation → Water rinse → Ultrasonic water rinse → Electroplating.

2. Chemical Immersion Plating

Due to the high chemical activity of NdFeB material, parts should be plated as soon as possible after activation. Otherwise, surface oxidation can easily occur, leading to poor adhesion between the coating and the substrate. Chemical immersion plating offers a much higher deposition rate than electroplating, effectively slowing down the oxidation process on the part surface during plating and thereby ensuring strong coating adhesion. For NdFeB, chemical immersion zinc or chemical immersion nickel processes can be selected.

3. Barrel Zinc Plating

The high chemical activity of NdFeB means that a zinc coating provides limited anodic protection to the substrate. Therefore, a high-density coating is required. However, the commonly used potassium chloride zinc plating process (or sulfate zinc plating + potassium chloride zinc plating) typically produces coatings with somewhat inferior density. These coatings also contain significant amounts of surfactants, resulting in lower quality of both the coating and the subsequent passivation film. Consequently, zinc plating for NdFeB is mostly used for lower-grade products or those intended for less demanding environments.

4. Barrel Nickel Plating

Barrel nickel plating for NdFeB typically employs a combined process of nickel-copper-nickel plating. This combination offers good coating adhesion, corrosion resistance, and decorative appearance, while having a moderate impact on the magnetic properties of the magnet.

Pre-plating Nickel (Base Layer): This serves a dual purpose: to enhance coating adhesion and to provide a base for the subsequent copper layer. The barrel dull nickel process is commonly used for this stage.

Copper Plating (Thickening Layer): This step increases the corrosion resistance of the composite coating and reduces its impact on the magnet’s magnetic properties. The barrel pyrophosphate copper process is often employed here.

Top Layer: A final layer of bright nickel is applied.

5. Electroless Nickel Plating (for Enhanced Performance)

If further improvement in corrosion resistance is required, an electroless nickel plating process can be chosen. Electroless nickel coatings exhibit low porosity and excellent corrosion resistance. Furthermore, by controlling the phosphorus content in the coating, the impact on the magnetic properties of the magnet can be minimized.

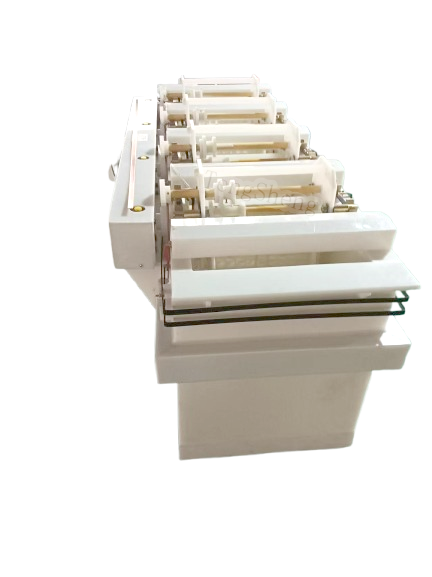

LT Series Four-Barrel Plating Machine – Technical Specifications

Each four-barrel unit consists of 1 plating tank with drive system and 4 barrels with brackets.

(1) Plating Tank & Drive System

Technical parameters are as follows:

| Model | Material | Overall Dimensions (L × W × H mm) | Tank Volume (L) |

|---|---|---|---|

| LT-S | Pure PP | 2100 × 750 × 850 | 585 |

| LT-S/W | Pure PP | 2200 × 800 × 900 | 585 |

| LT-S-B | Pure PP | 2100 × 750 × 850 | 585 |

| LT-S/W-B | Pure PP | 2200 × 800 × 900 | 585 |

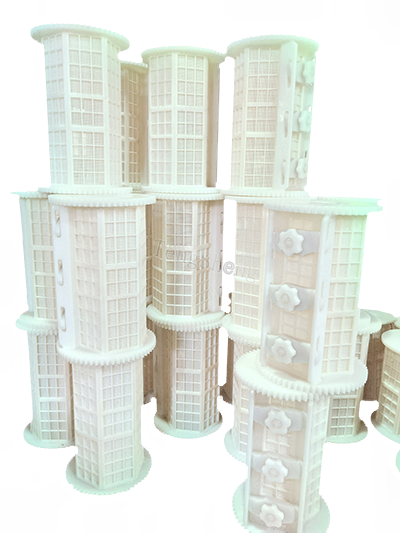

Technical Parameters and Specifications

| Model | Barrel Dimensions | Perforation Type | Specifications (Available Sizes) |

|---|---|---|---|

| GD-2.5 | 280 × Ø 120 mm | Mesh Hole | 2mm×2mm, 1mm×1mm, 0.5mm×0.5mm, 0.2mm×0.2mm |

| Square Hole | 2mm×2.5mm, 2mm×2mm (With protrusions on the inner barrel wall), 0.7mm×5.5mm | ||

| Round Hole | Customized as required | ||

| GD-3.5 | 280 × Ø 140 mm | Mesh Hole | 1mm×1mm, 0.5mm×0.5mm |

| Square Hole | 0.3mm×5.5mm | ||

| Round Hole | Customized as required | ||

| GD-5 | 280 × Ø 170 mm | Mesh Hole | 2mm×2mm, 1mm×1mm, 0.5mm×0.5mm, 0.3mm×0.3mm, 0.2mm×0.2mm |

| Square Hole | 2mm×2.5mm, 2mm×2mm (With protrusions on the inner barrel wall), 0.7mm×5.5mm | ||

| Round Hole | Customized as required |